MST Provides Residual Sulfur For Following Crop Uptake

Sulvaris developed Micronized Sulfur Technology (MST®) as

At Sulvaris, we develop proprietary technologies that transform industrial co-products into agronomically and environmentally friendly fertilizer products.

Research & Development

We strive to drive new innovation and technologies that create value on the farm and for our partners through sustainable solutions. With proven science and trial data we’ve demonstrated year after year that products using Sulvaris technologies deliver improved agronomic benefits compared to other alternatives.

These agronomic benefits include: improved nutrient delivery, availability and uptake throughout the growing season that is better aligned with crop needs, reduced application costs due to higher nutrient density, greater flexibility in application placement and timing, higher yield response and reduced environmental impact.

All research was conducted by independent 3rd party organizations including universities and contract research organizations across the United States and Canada.

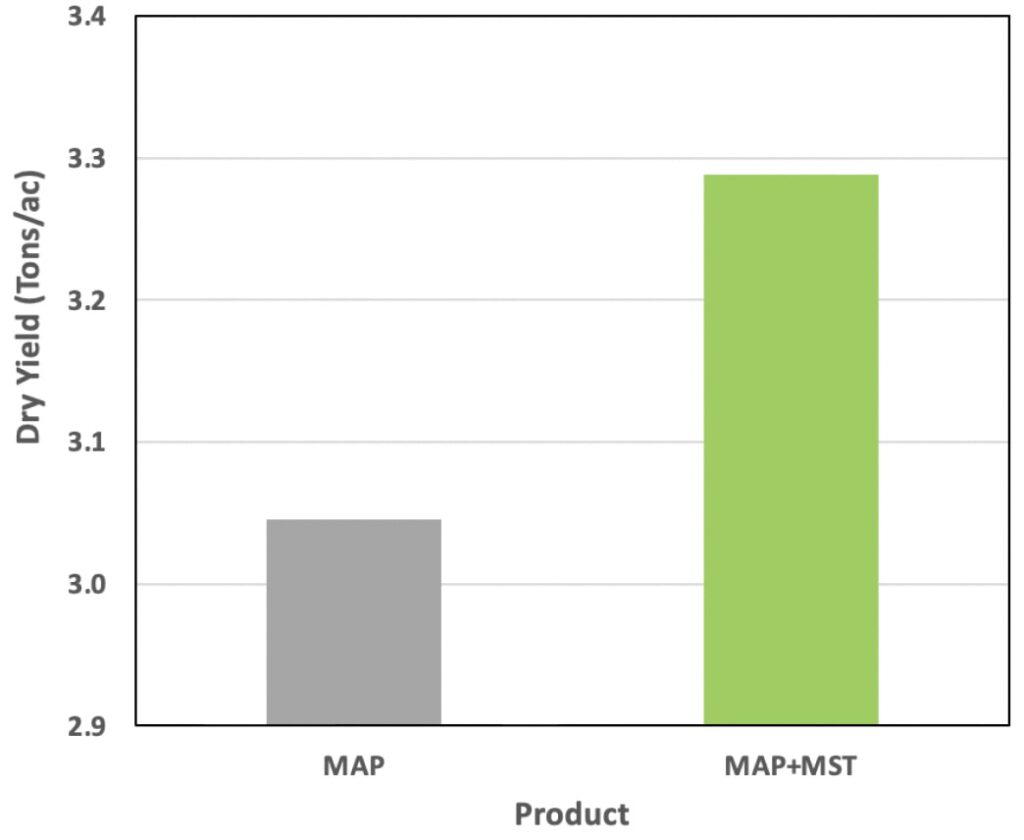

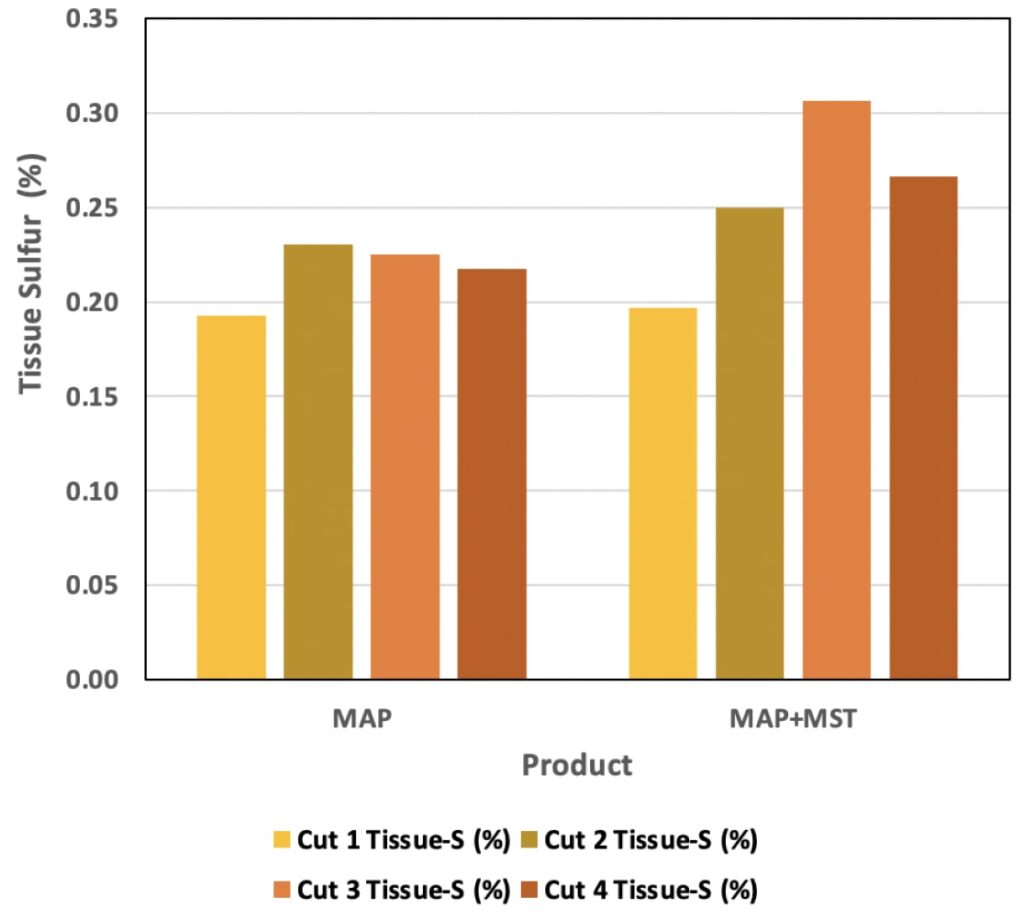

Alfalfa dry yield (season total) and tissue sulfur concentrations with each cut from 4 site years. MAP+MST increased yield by 0.24 tons/ac over MAP.

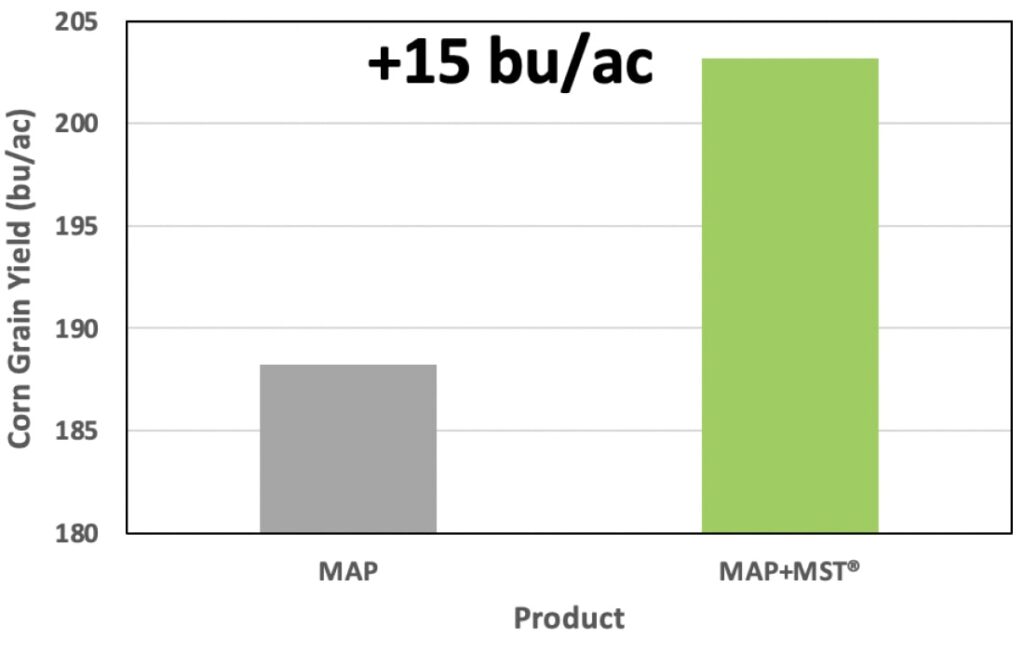

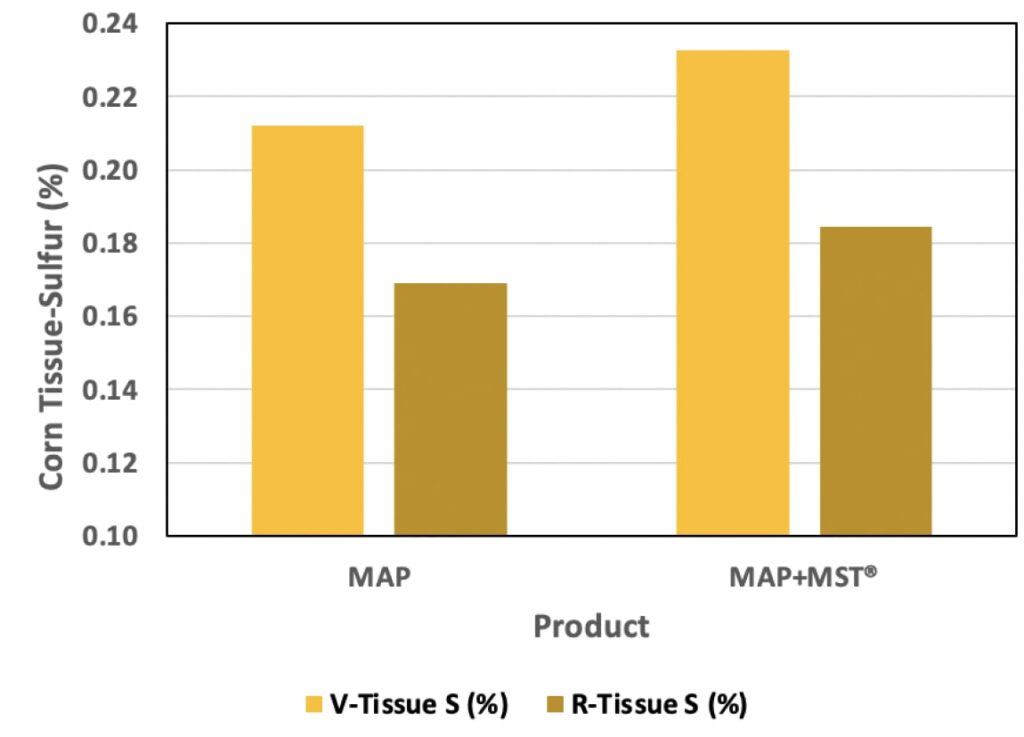

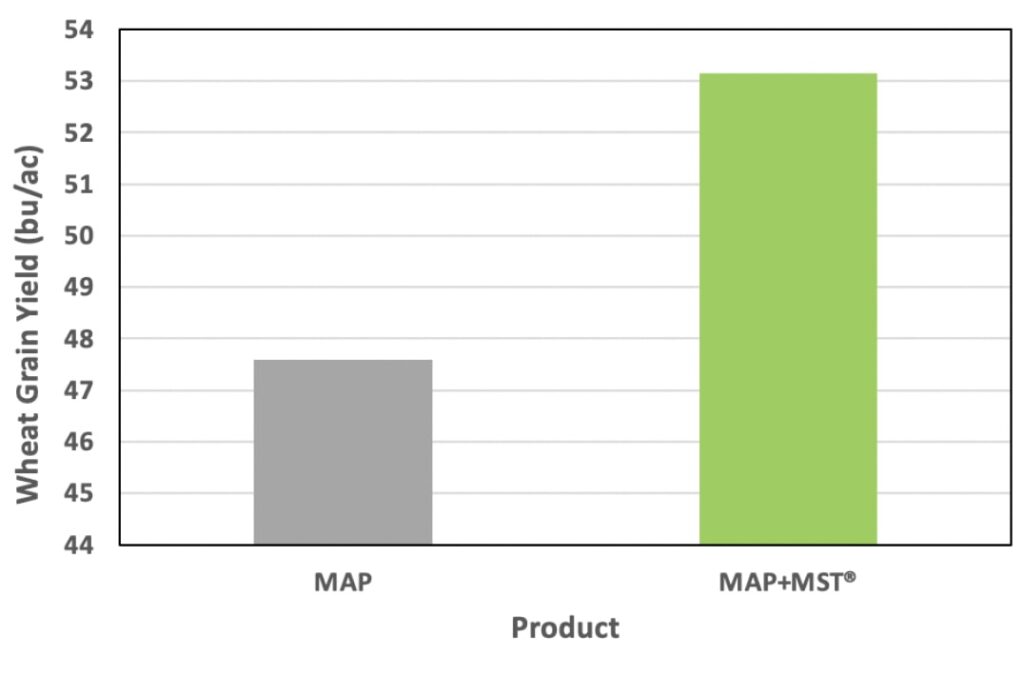

Average of all testing at 55 site-years (2018-2020). MAP+MST increased yield by 15 bu/ac over MAP.

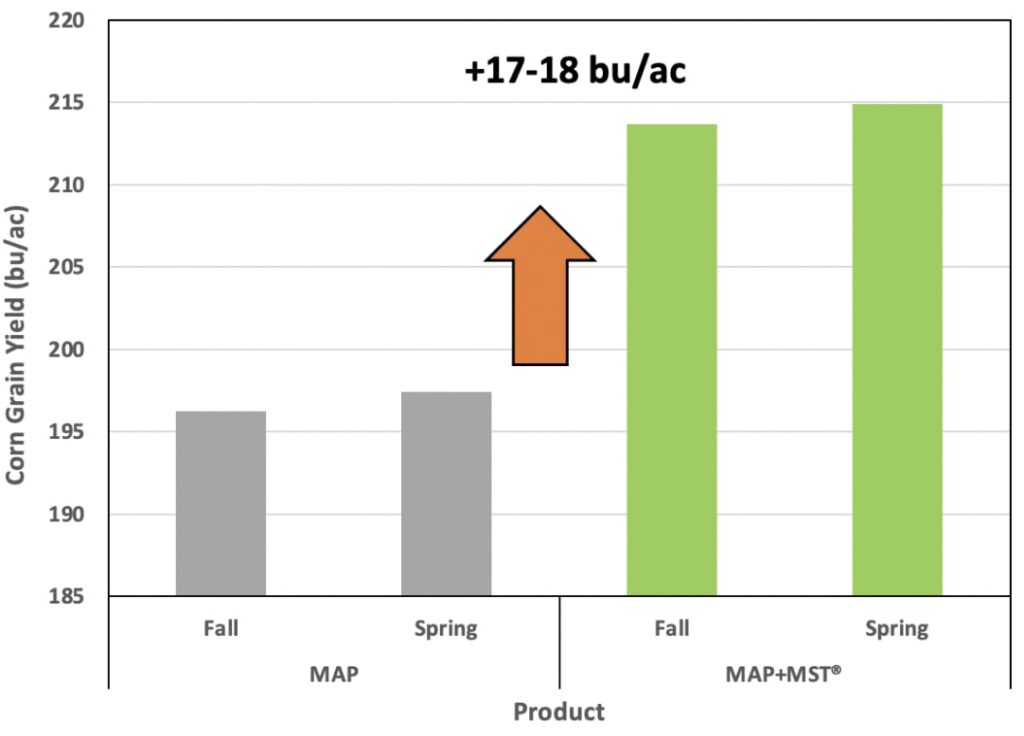

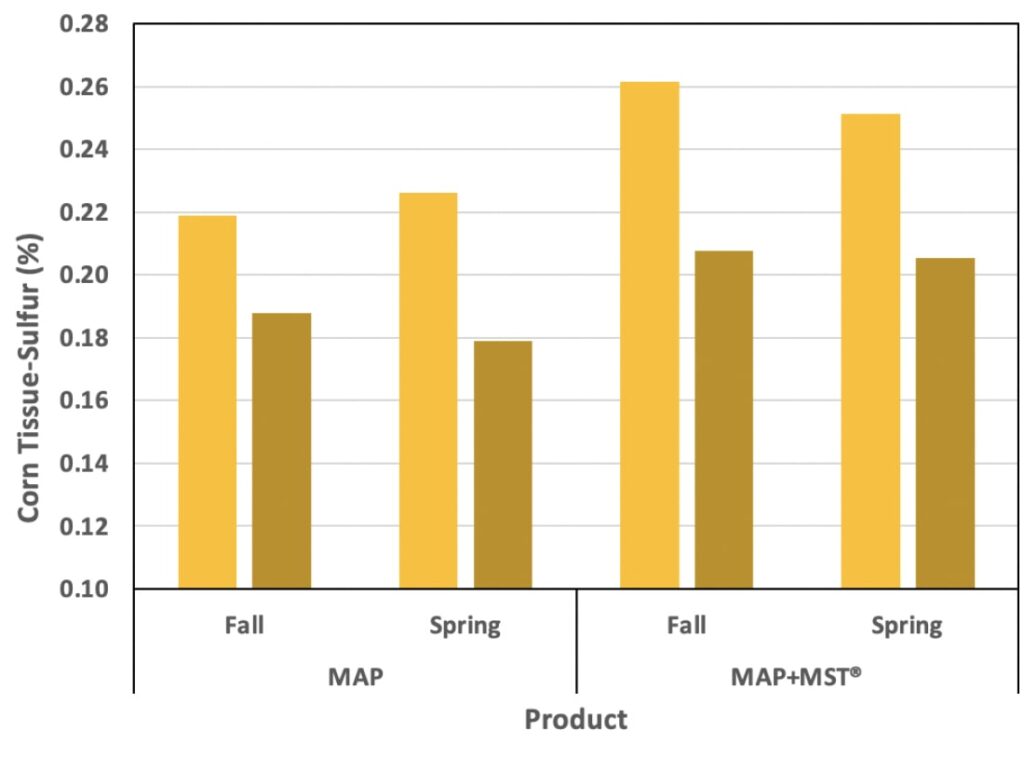

Average grain yield from 12 site-years comparing fall to spring fertilizer application, demonstrating 17-18 bu/ac yield increase. MAP+MST is suitable in fall or spring applications.

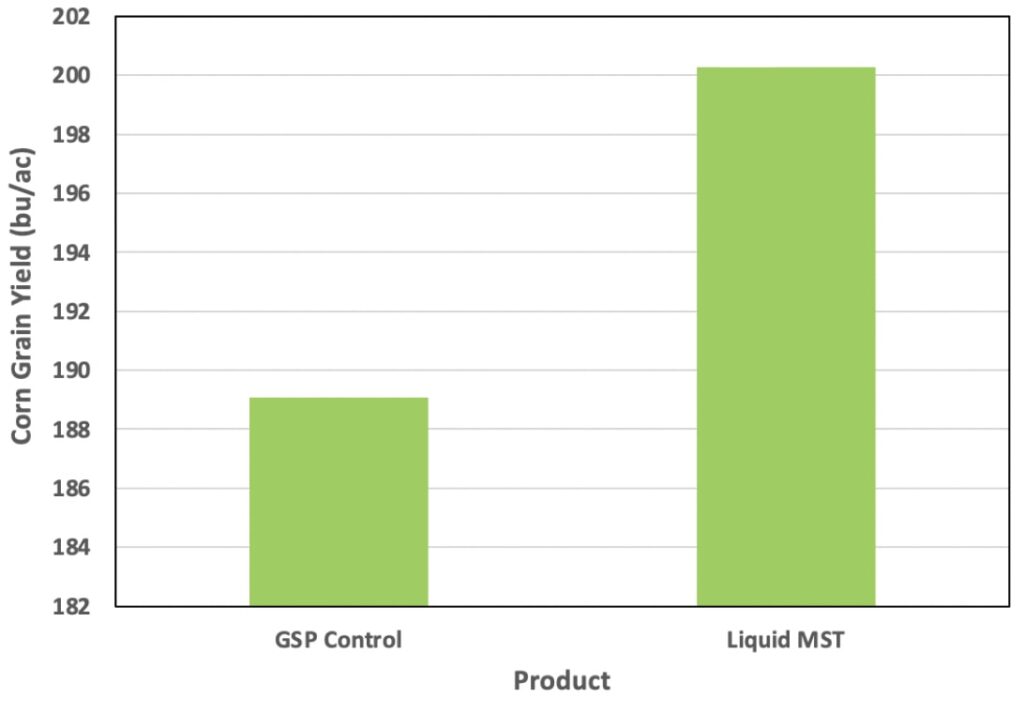

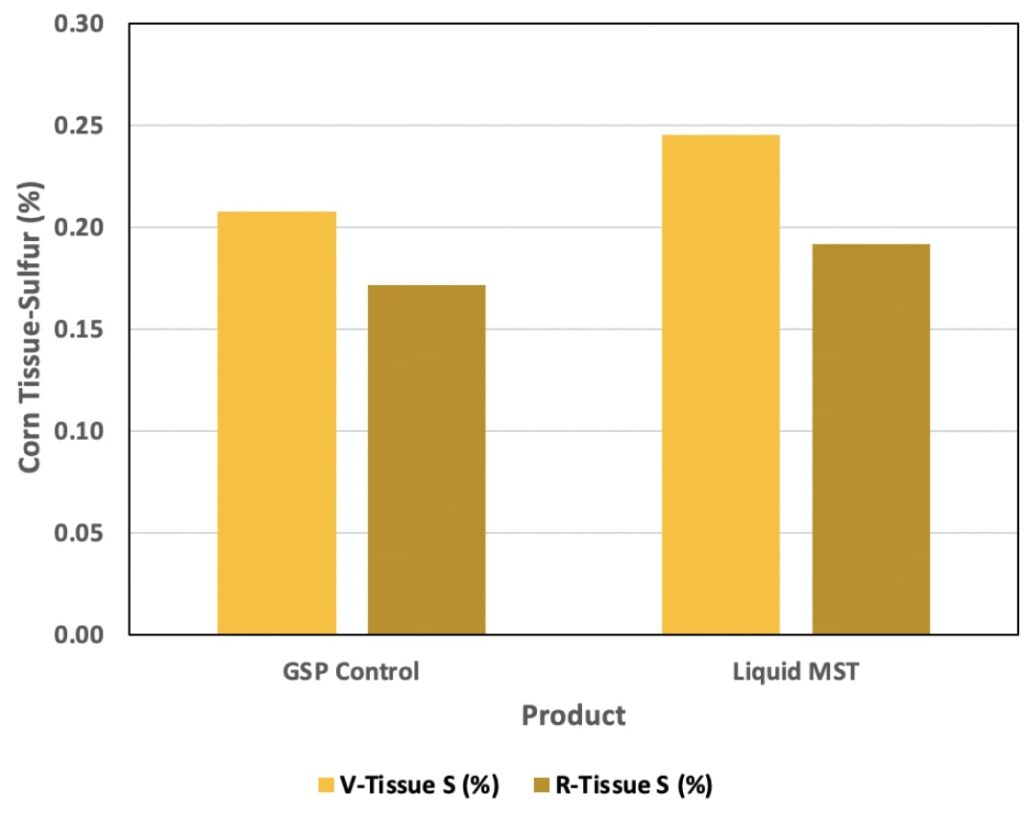

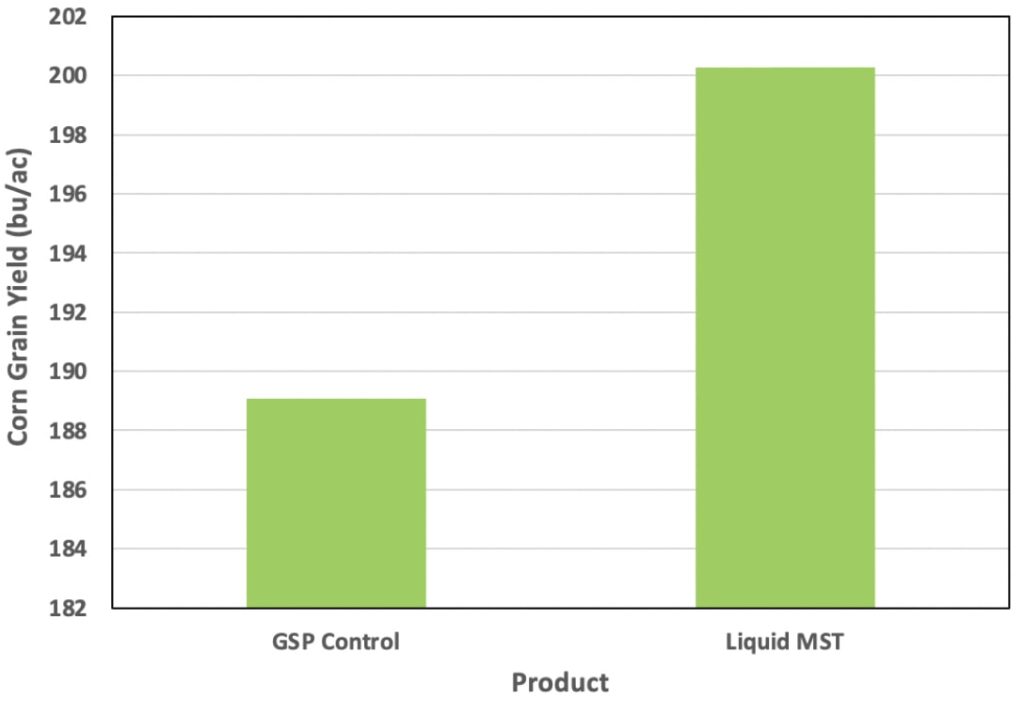

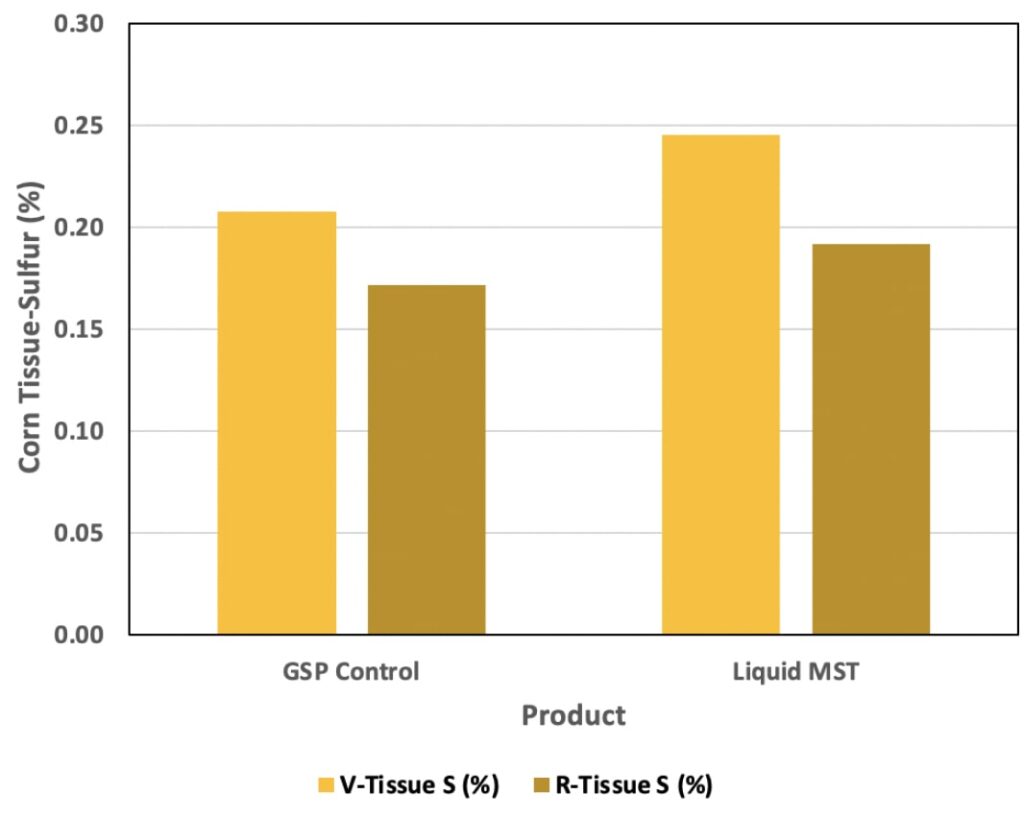

Average corn grain yield over 65 site-years, and tissue sulfur concentrations at critical vegetative (V) and reproductive (R) growth stages. Liquid MST increased yield by 11 bu/ac over GSP control receiving no sulfur.

Average grain yield from 7 site-years with Liquid MST applied at planting or at side-dress. Liquid MST demonstrates flexibility in application timing, with a yield increase between 7 – 8% above the control, and season long sulfur availability. Tissue samples taken at vegetative (V) and reproductive (R) growth stages.

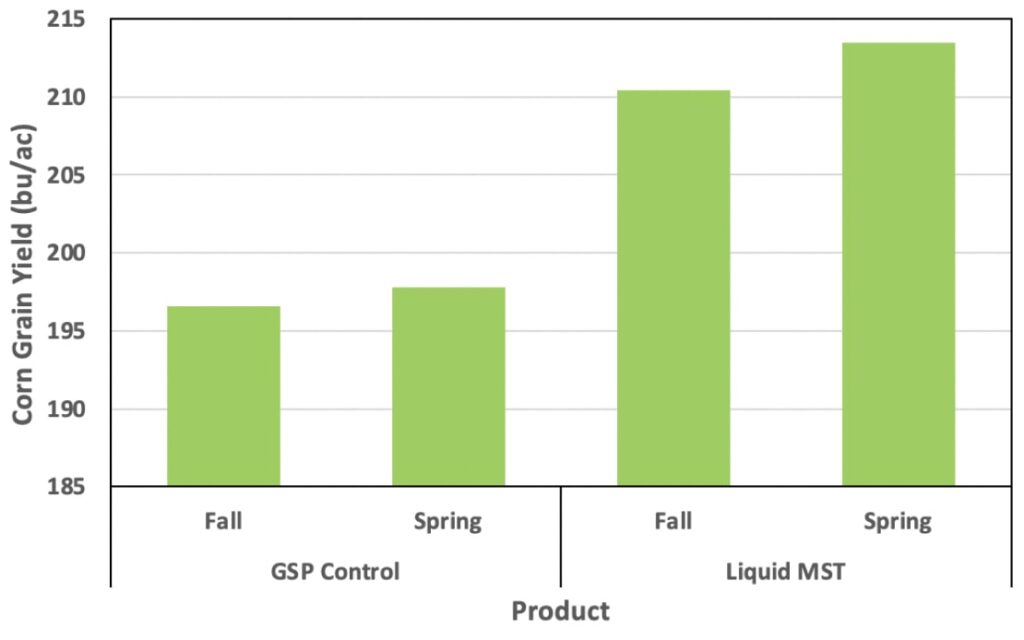

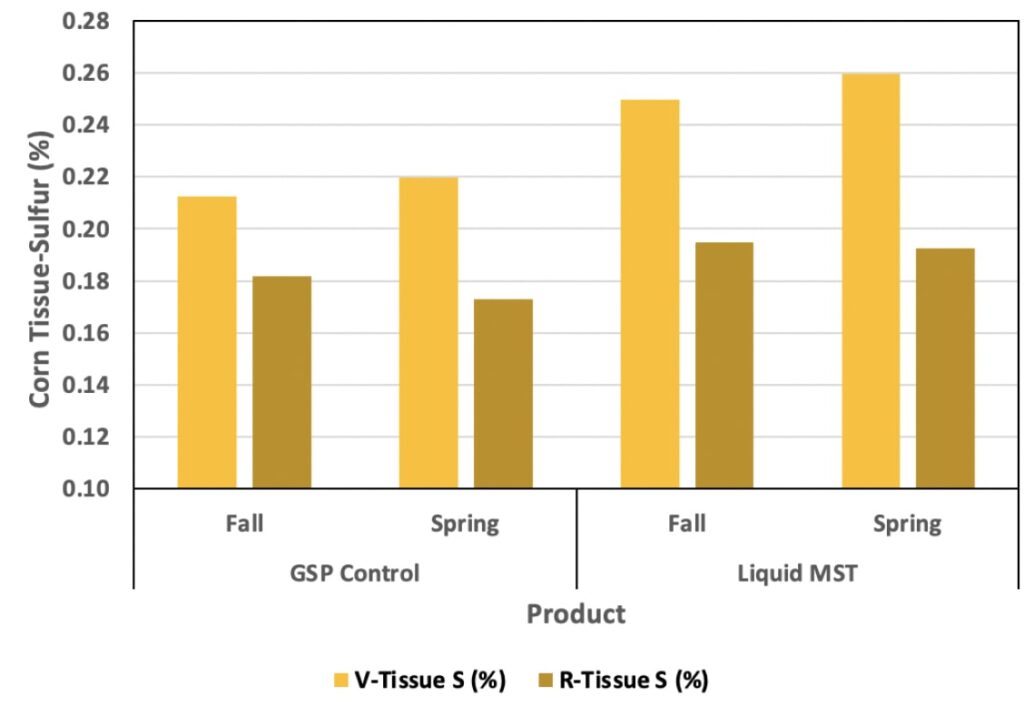

Average grain yield from 7 site-years with Liquid MST applied at planting or at side-Average grain yield and tissue sulfur concentrations at vegetative and reproductive growth stages from 12 site-years of fall vs spring applied trials. Liquid MST increased yield by 14-16 bu/ac whether applied in the fall or spring.

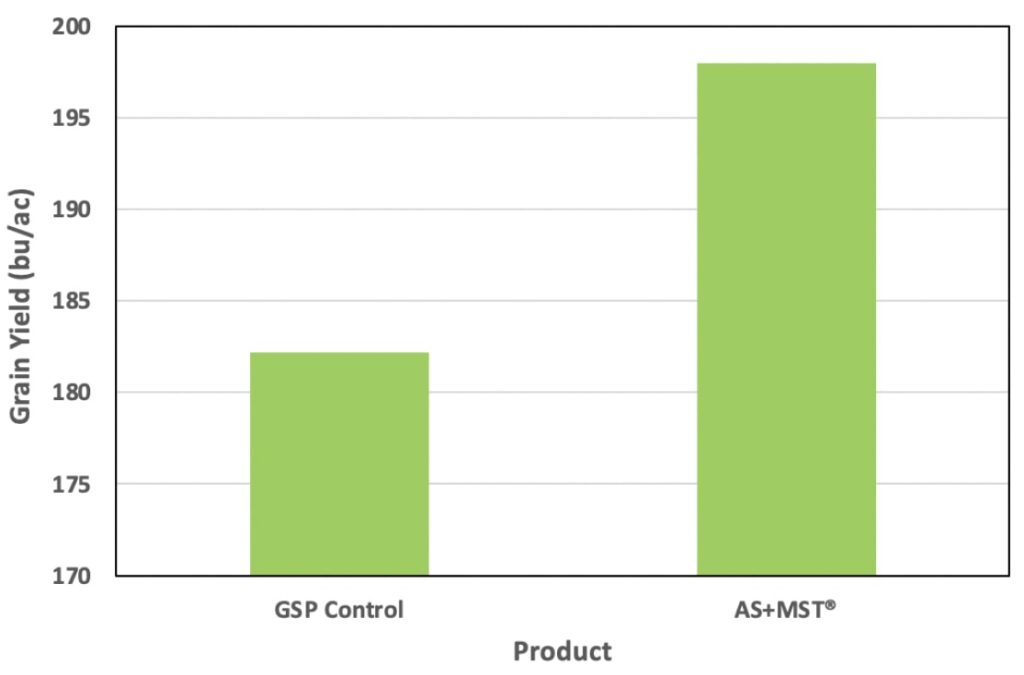

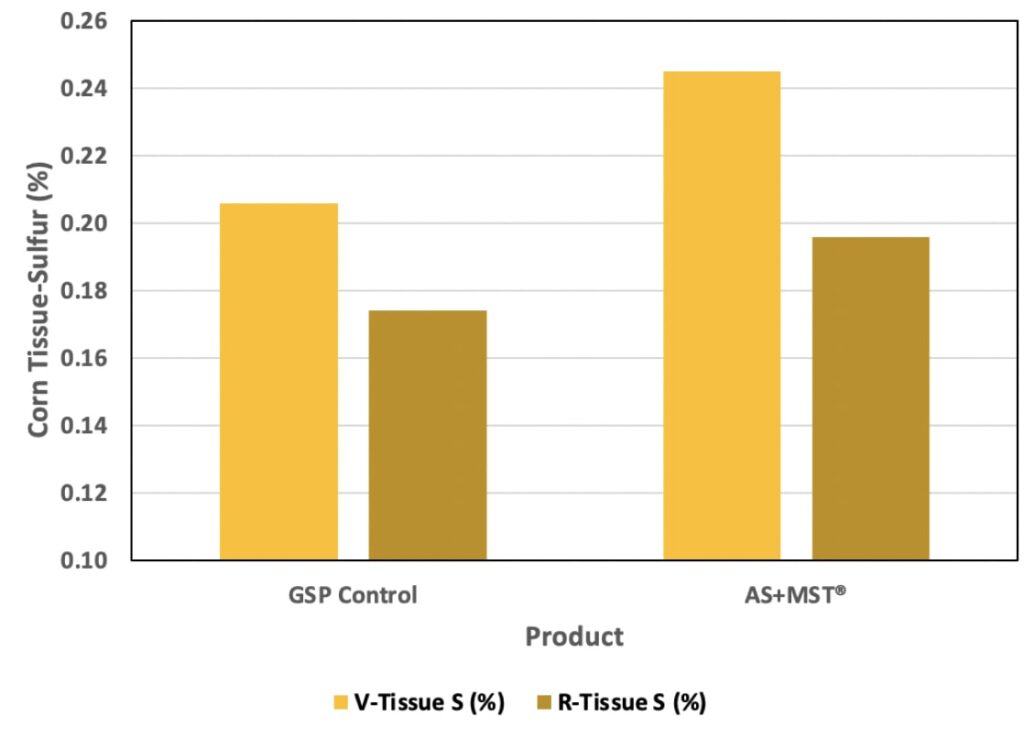

Average grain yield from 24 site-years in 2019-2020, and tissue sulfur concentrations at vegetative (V) and reproductive (R) growth stages. AS+MST increased yield by 16 bu/ac, and demonstrated increased tissue sulfur concentrations compared to a GSP control without sulfur.

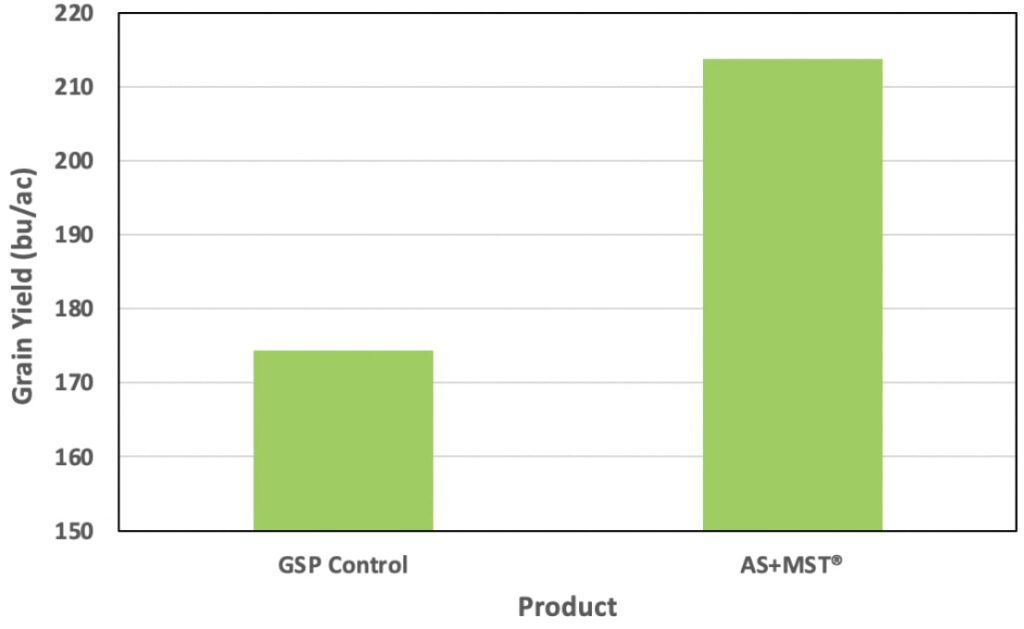

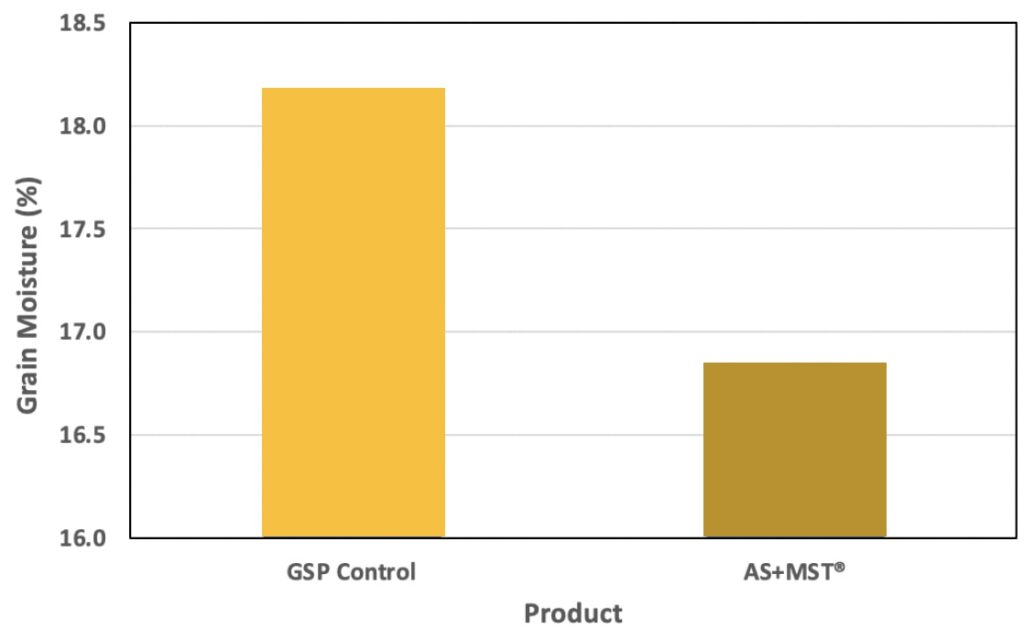

AS+MST increased yield by 16 bu/ac, and demonstrated increased tissue sulfur concentrations compared to a GSP control without sulfur. AS+MST increased grain yield by 39 bu/ac, and grain moisture at harvest was 1.3% lower that the GSP without sulfur.

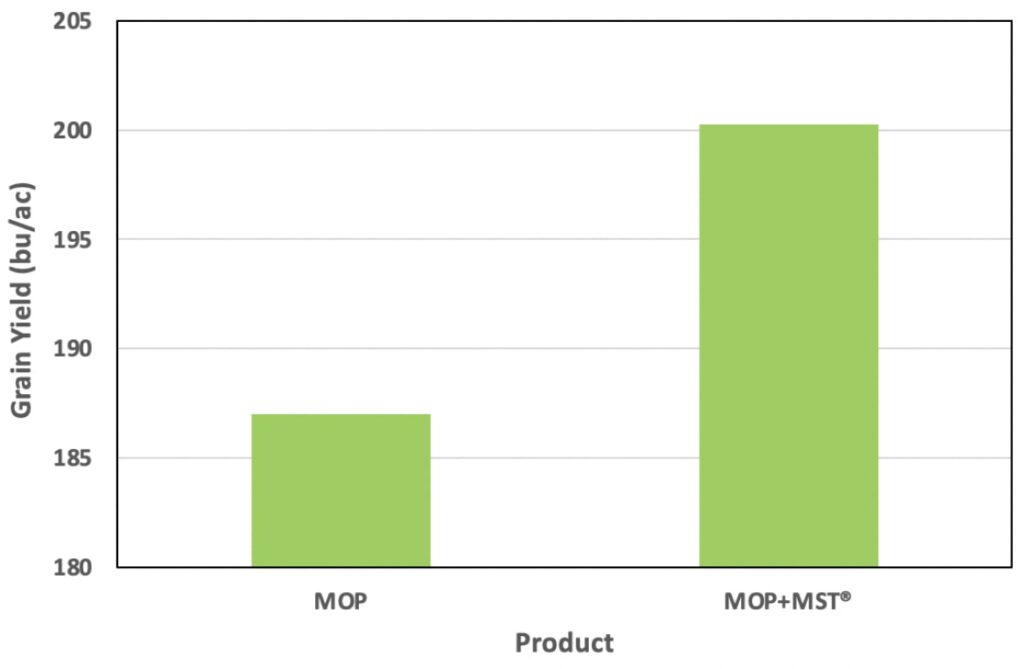

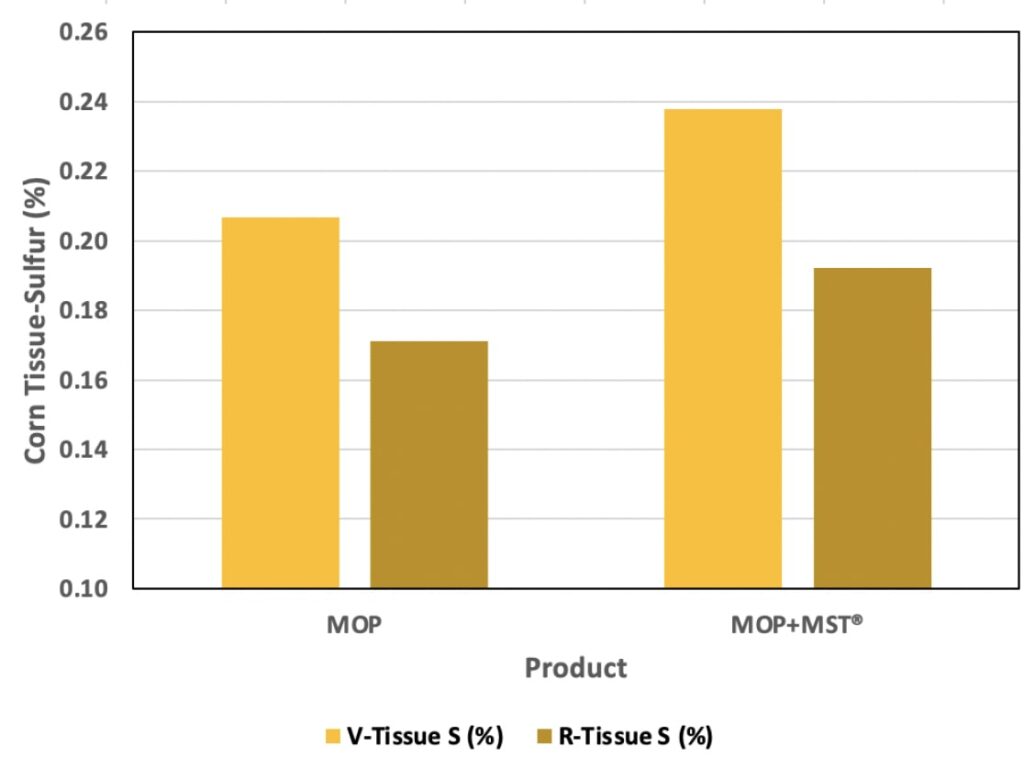

Average grain yield from 53 site-years from 2017-2020, and tissue sulfur concentrations at vegetative (V) and reproductive (R) growth stages. MOP+MST increased yield by 13 bu/ac compared to MOP alone.

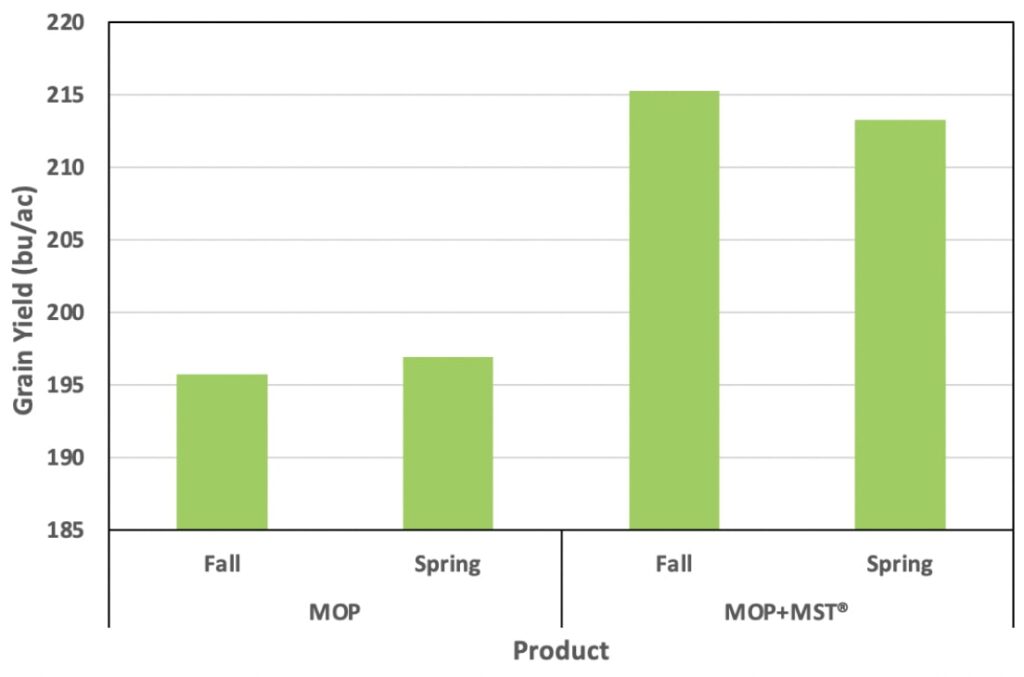

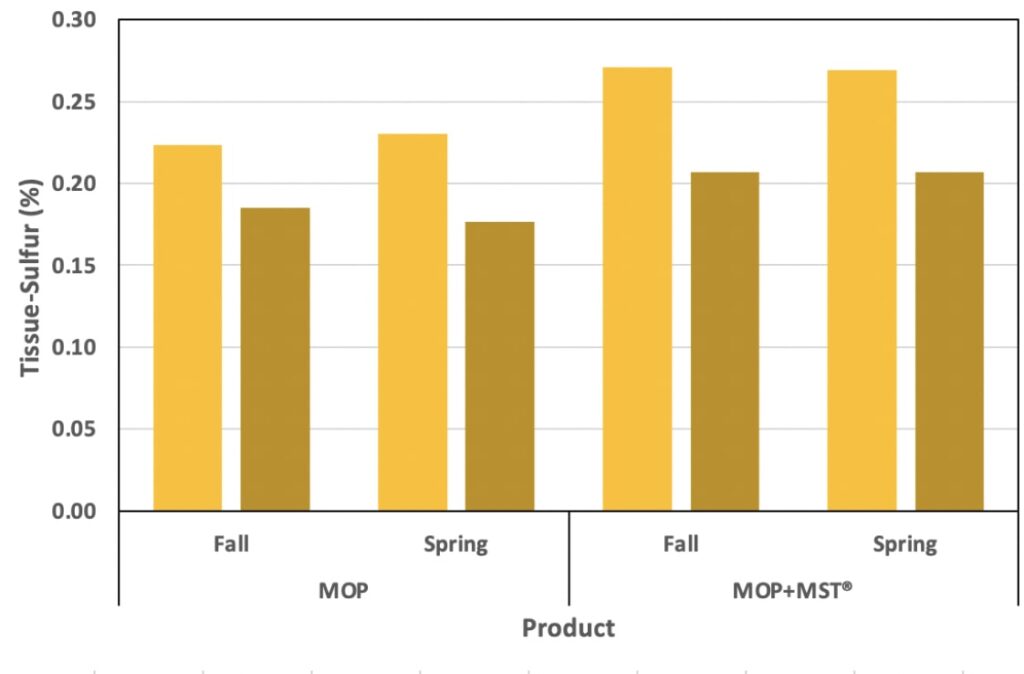

Average grain yield from 12 site-years from 2017-2020 (L), and tissue sulfur concentrations at vegetative and reproductive growth stages (right). MOP+MST increased corn grain yield by 16-20 bu/ac when applied either in the fall or spring, compared to MOP, demonstrating flexibility in application timing.

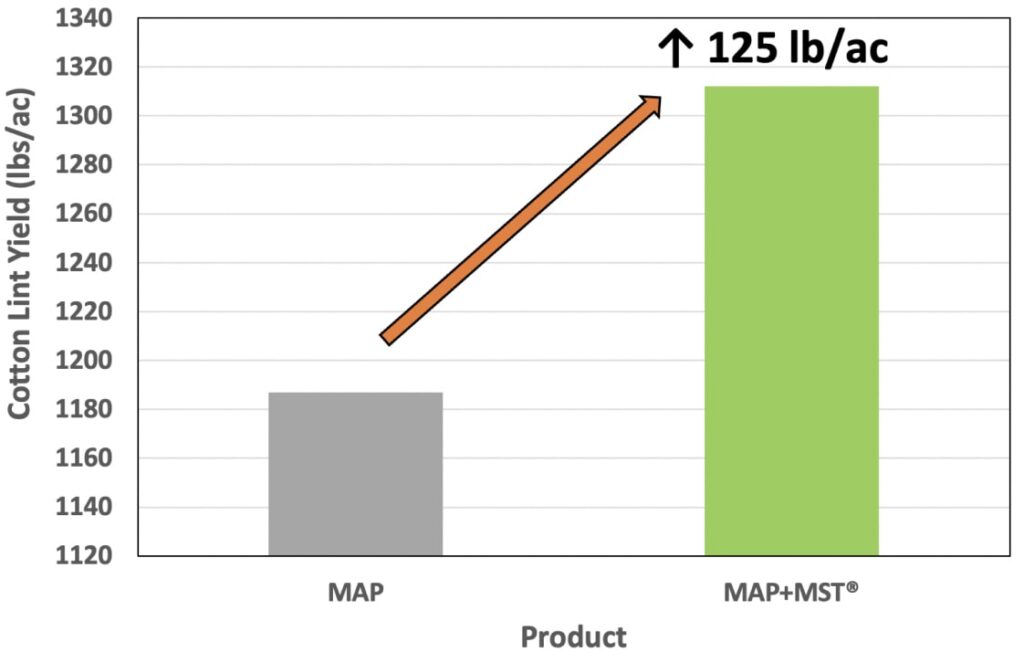

Average lint yield from 12 site-years (2018-2020). MAP+MST increased yield by 125 lb/ac over MAP.

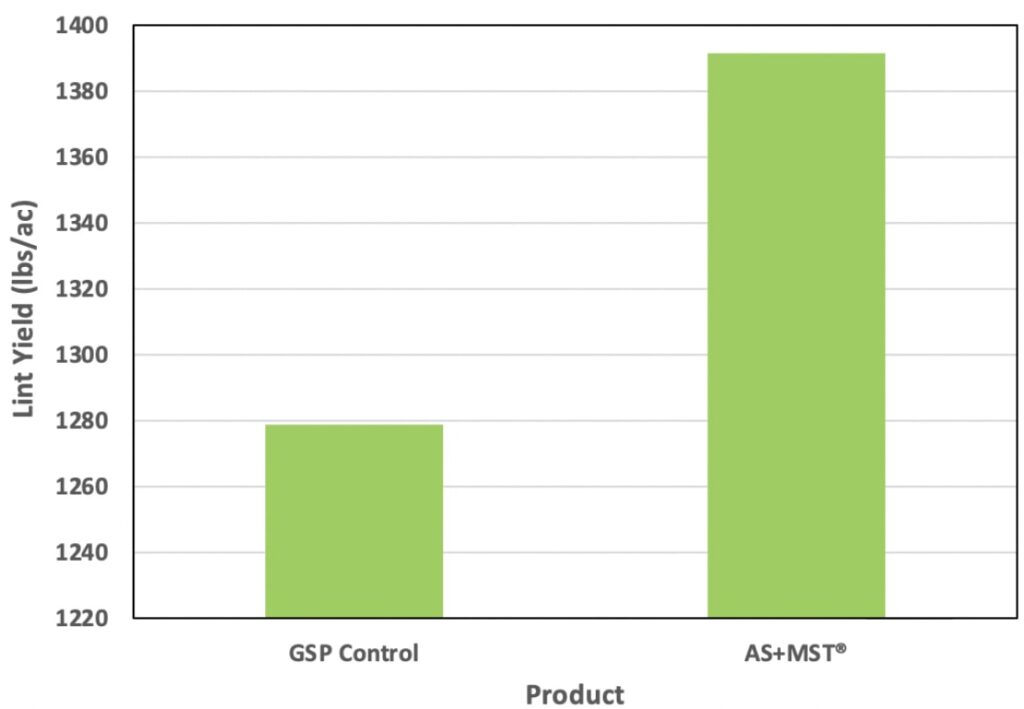

Average cotton lint yield from 10 site-years in 2019 and 2020. Lint yield was increased by 112 lbs/ac with AS+MST over the GSP without sulfur

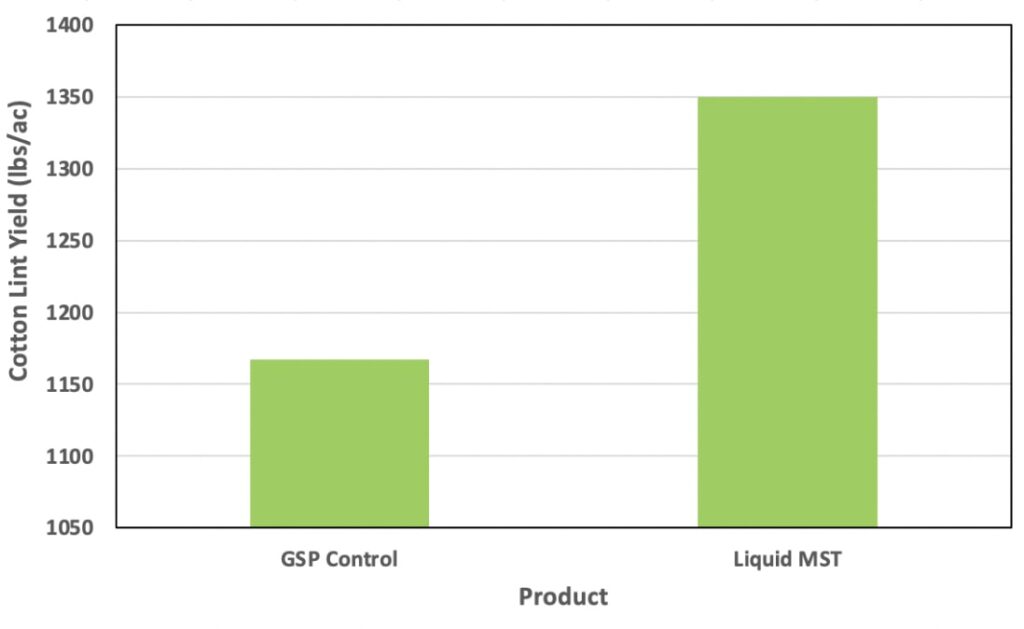

Average cotton lint yield from 15 site-years (2017-2020). Liquid MST increased yield by 183 lbs/ac (16%) over the control. Liquid MST can be applied at plant compared to thiosulfate which is often applied at side-dress to reduce leaching potential.

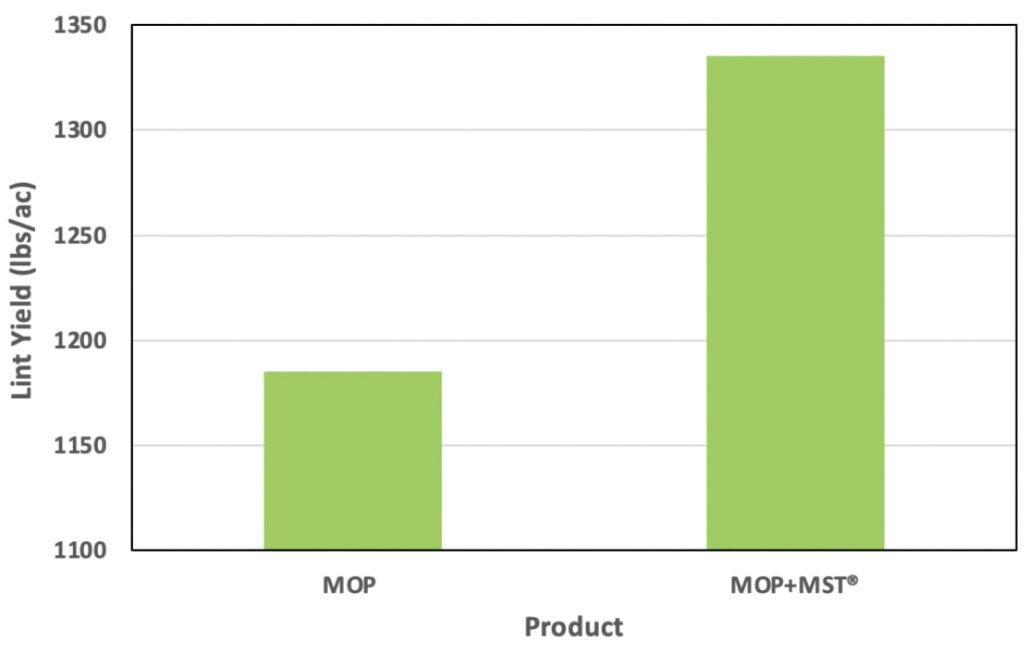

Average cotton lint yield from 16 site-years from 2017-2020. MOP+MST increased lint yield by 150 lb/ac compared to MOP

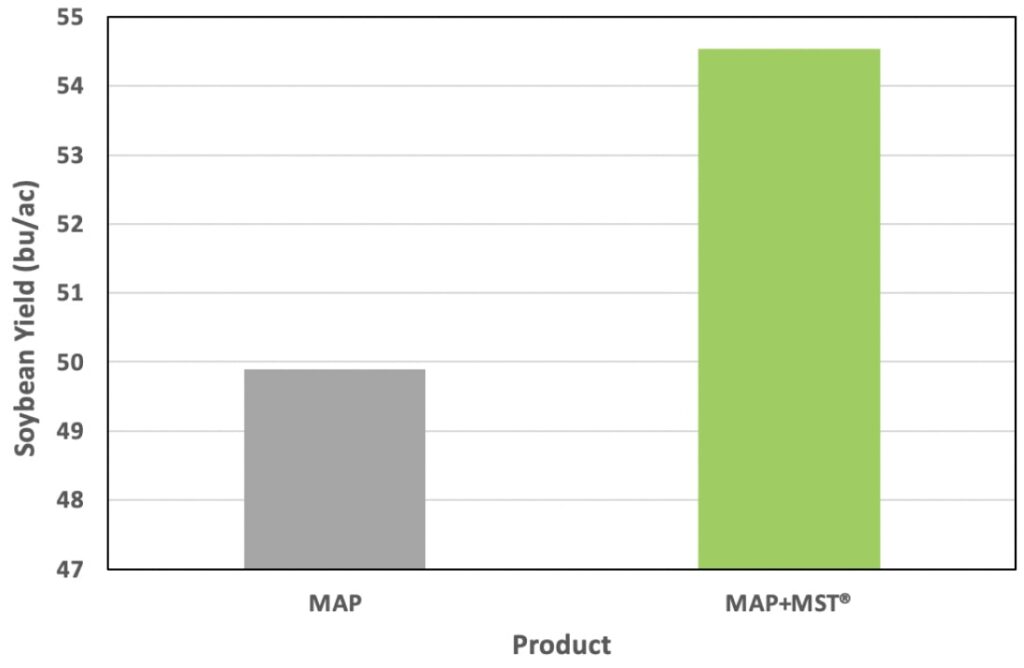

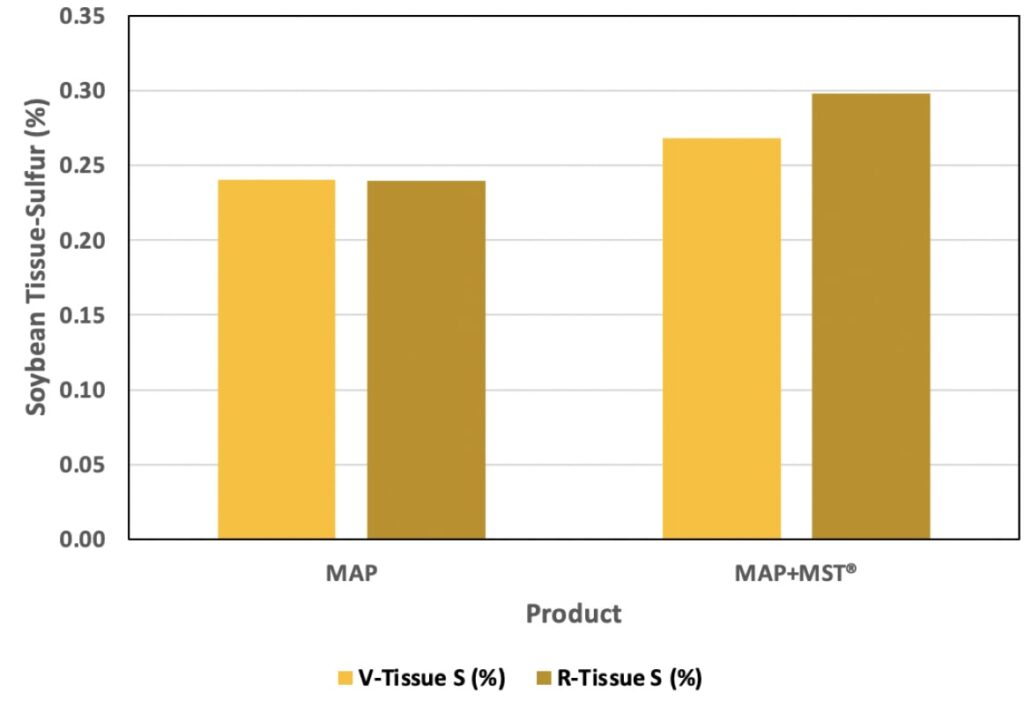

Average soybean yield from 4 site-years at highly sulfur responsive locations (2018-2020). MAP+MST increased yield by 4.6 bu/ac over MAP. Tissue sulfur concentrations indicate sulfur is available at critical vegetative and reproductive growth stages.

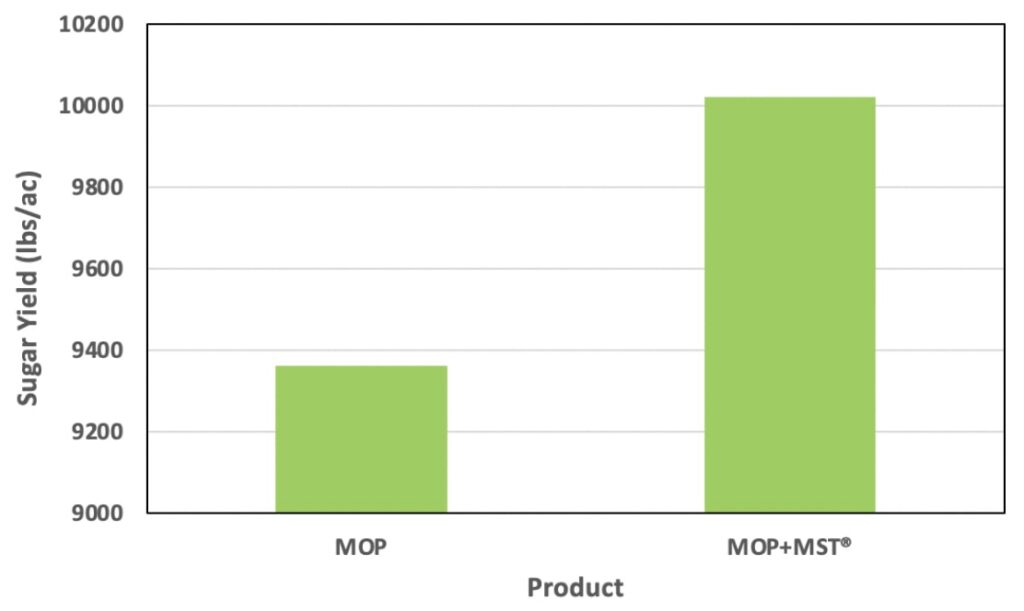

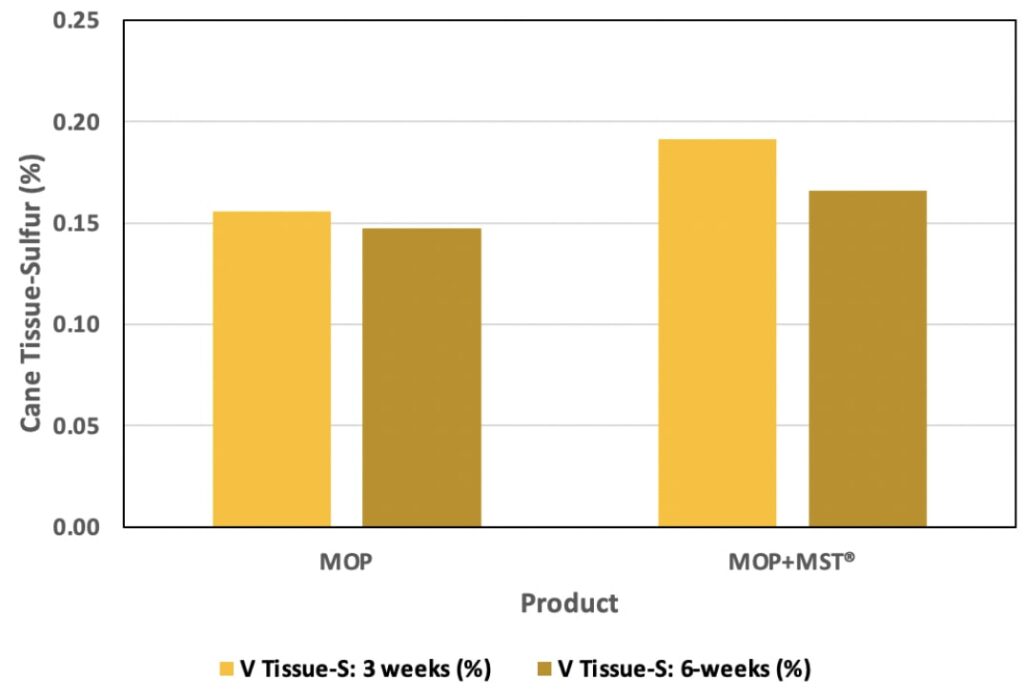

Average sugar yield from 12 site-years from 2017-2020. MOP+MST increased sugar yield by 659 lbs/ac compared to MOP, and had higher tissue sulfur concentration throughout the growing season.

Average winter wheat yield from 3 site-years (2018-2020). MAP+MST increased yield by 11% over MAP.

All research was conducted by independent 3rd party organizations including universities and contract research organizations across the United States and Canada.

Sulvaris developed Micronized Sulfur Technology (MST®) as

Sulvaris Inc., Calgary, and Machinefabriek Kreber B.V., Netherlands, are

Latest News

A Fertilizer containing micronized elemental Sulphur and Ammonium Sulphate

A brand-new Ammonium Sulphate fertilizer containing micronized sulphur

A revolutionary carbon-based, ammonium phosphate product

A revolutionary carbon-based, ammonium sulphate product

19% N, 21% S, 5% C (19-0-0-21-5C)

SGN: 290-320 (2.9-3.2mm)

Uniformity index > 60

Crushing strength > 4.5 kg (10lb)

HIGH RTA and LOW dust

Flexible process allows for alteration of nutrient analysis and carbon content, as well as the addition of micronutrients

A Broad Acre Potash and Sulphur Fertilizer

Potash MST® granules produced at IFDC

A brand-new potash fertilizer containing micronized sulphur

Traditional Elemental Sulphur Products

(75-2000 micron size avg 960)

Specialty Products with Elemental Sulphur

(50-200 micron size avg 150)

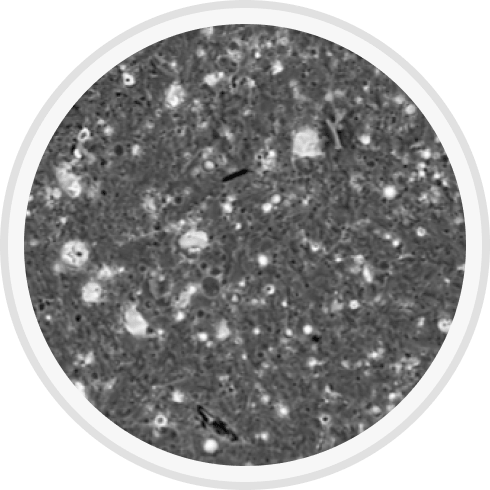

Sulvaris MST® Particle Size

(1-12 micron size avg 7)

A broad acre phosphate fertilizer containing micronized elemental Sulphur

Phos MST® has all three nutrients evenly dispersed through every granule

Traditional Elemental Sulphur Products

(75-2000 micron size avg 960)

Specialty Products with Elemental Sulphur

(50-200 micron size avg 150)

Sulvaris MST® Particle Size

(1-12 micron size avg 7)

A broad acre fertilizer containing micronized elemental Sulphur and Urea

A brand-new Urea fertilizer containing micronized sulphur

Traditional Elemental Sulphur Products

(75-2000 micron size avg 960)

Specialty Products with Elemental Sulphur

(50-200 micron size avg 150)

Sulvaris MST® Particle Size

(1-12 micron size avg 7)

A broad acre liquid fertilizer containing micronized elemental Sulphur

Advantages

On average, Liquid MST® has provided greater yield responses than ammonium thiosulfate across all site-years studied.

The sulphur in MST® is immobile in the soil until it is oxidized to sulphate. Liquid MST® has less leaching than ATS and can be readily integrated into fall and early spring applications.

Liquid MST® does not have a high salt or nitrogen component that can damage germinating seeds, or foliage.

This is a high analysis sulphur product, meaning a lower volume of product is required to achieve sulphur requirements.

Liquid MST® is suitable for side dress applications.

Liquid MST® has a lower carbon footprint than tradition sulphur products such as ATS or AS.

Liquid MST® allows all of the crop’s sulphur requirements to be provided from one source, creating an opportunity to choose an environmentally responsible N source.