MST Provides Residual Sulfur For Following Crop Uptake

Sulvaris developed Micronized Sulfur Technology (MST®) as

At Sulvaris, we develop proprietary technologies that transform industrial co-products into agronomically and environmentally friendly fertilizer products.

Micronized Sulphur Technology®

The transformative power of Sulvaris®’ Micronized Sulphur Technology (MST®) unlocks the nutritional value of elemental sulphur within the growing season, without the risk of the sulphate form of sulphur moving below the root zone of the crop, making it unavailable and a potential polutant.

Sulphur is essential for life on earth. As one of the fundamental “macronutrients,” including nitrogen (N), phosphorus (P) and potassium (K), sulphur has a key role in crop development and growth.

A growing problem: Sulphur levels have been declining for years, severely limiting crop production in many parts of the world.

Global grain and oilseed production is struggling to keep up with consumption, which has risen at an annualized rate of 2.2 percent over the past decade.

More growers are switching to sources with little or no sulphur– like urea or MAP. Because of this, less plant nutrient sulphur (PNS) is being applied through macronutrient sources.

Global industry has cut SO2, “greenhouse gas” emissions to reduce acid rain. While this is environmentally positive overall, it has also reduced regionally concentrated supplies of PNS.

Today’s high-performance seed hybrids require significantly more PNS, and they need it throughout the season to maximize yield potentials.

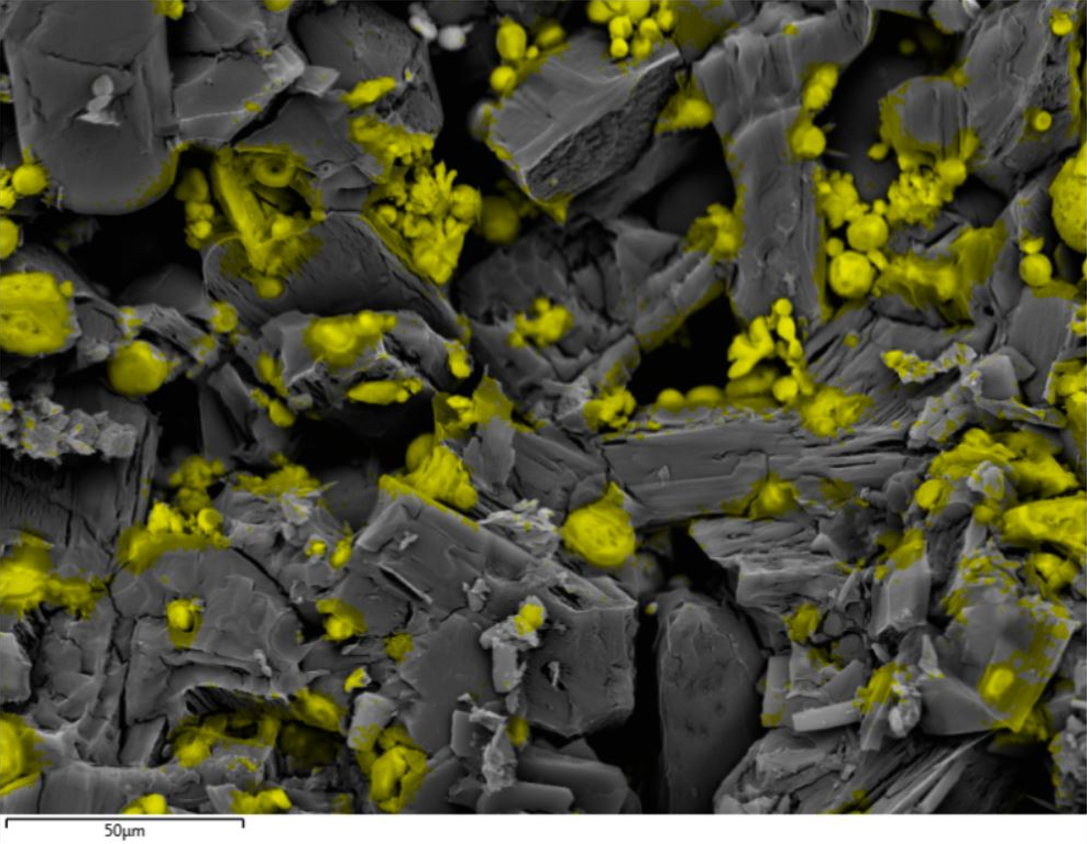

Micronized Sulphur Technology (MST®) is a proprietary patented technology that micronizes sulphur to less than 7-microns, which is the smallest particle size economically produced on a commercial scale in the industry to date.

Smaller particle size distribution leads to an exponential increase in the surface area, which is essential for microbial oxidation to convert otherwise insoluble sulphur into a soluble nutrient form available for plant uptake.

Elemental sulphur oxidation rates are temperature-dependent, so the MST® component will transform to sulphate as soils warm through the spring, and summer months.

In locations of high precipitation, the MST® component will not leach from soils in high rainfall events until it is transformed to sulphate by soil microorganisms. This increases the sulphur available in the root zone.

Quick and prolonged sulphur oxidation for season long availability.

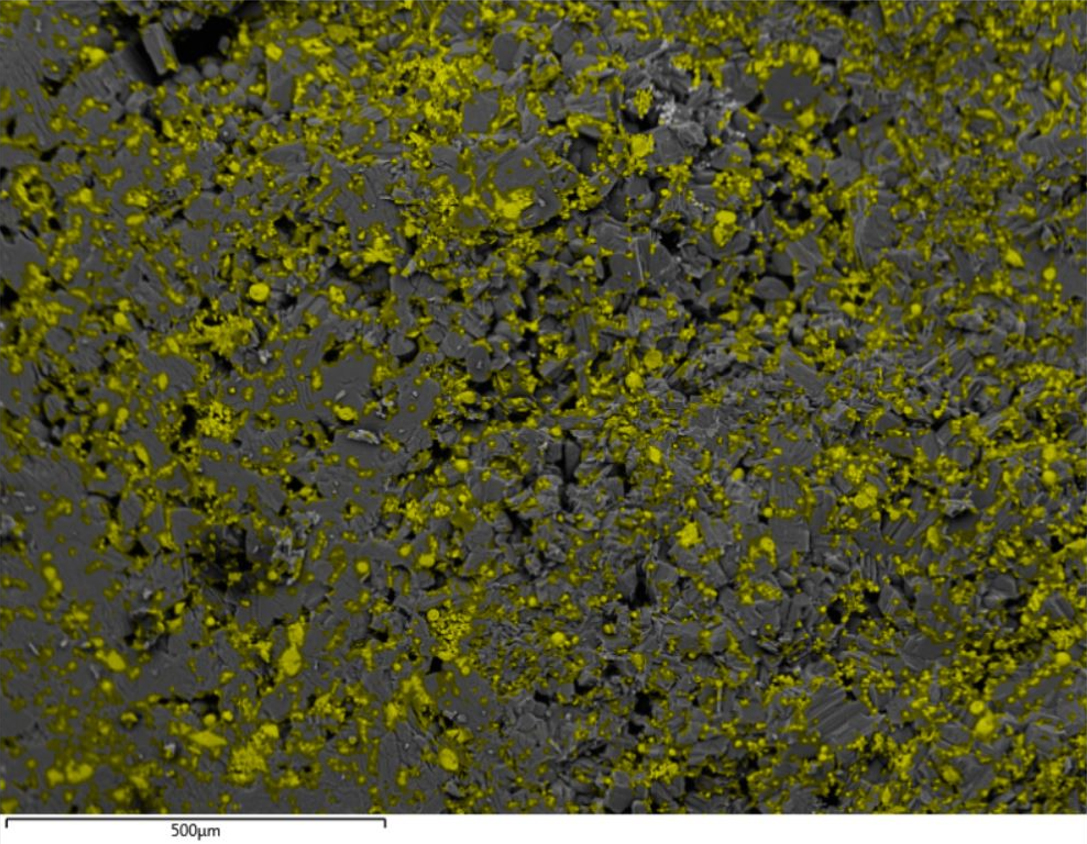

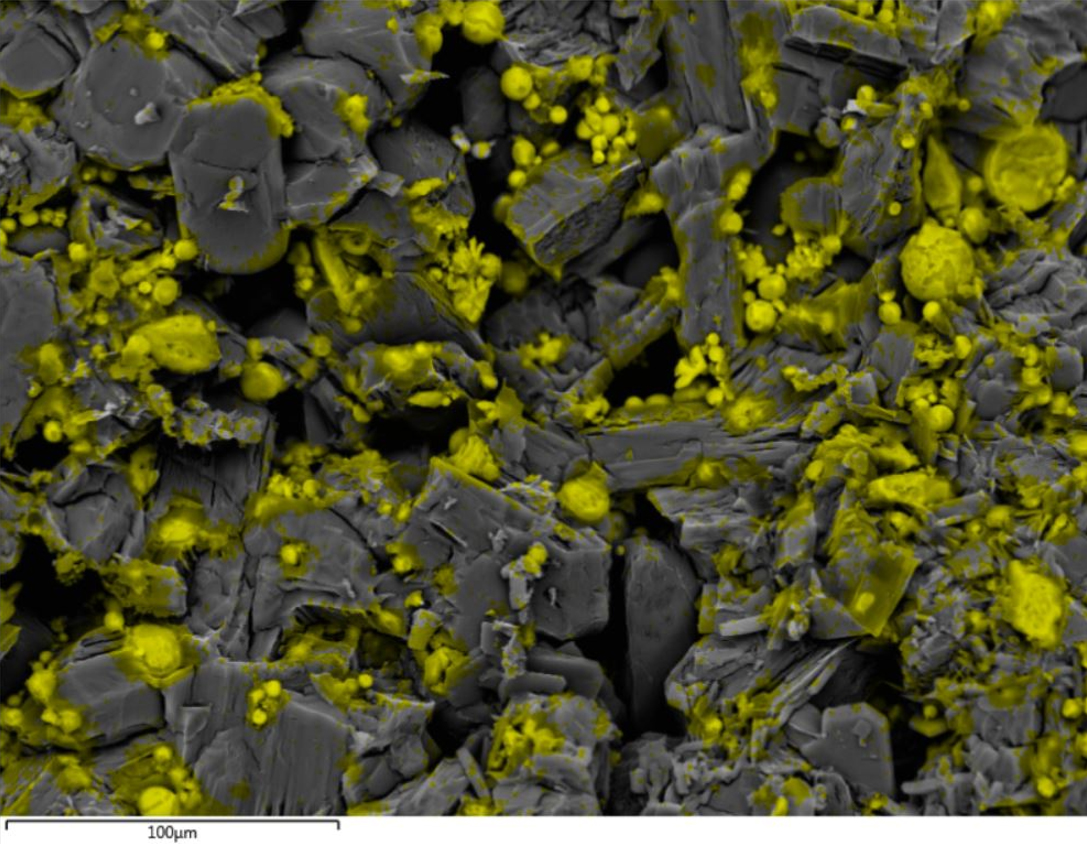

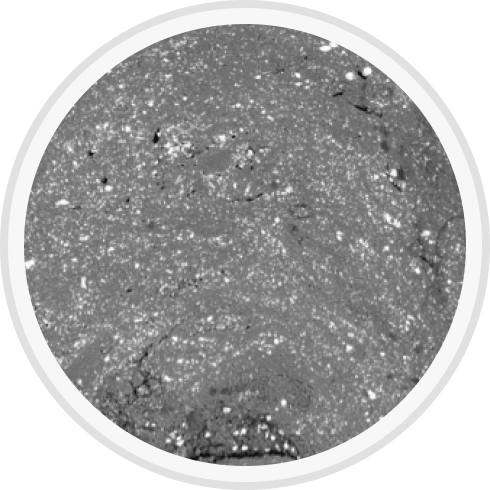

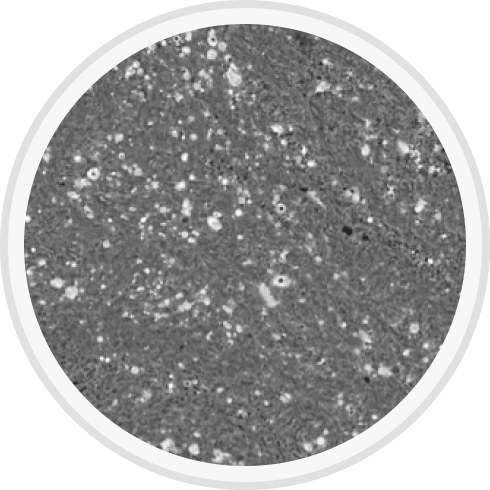

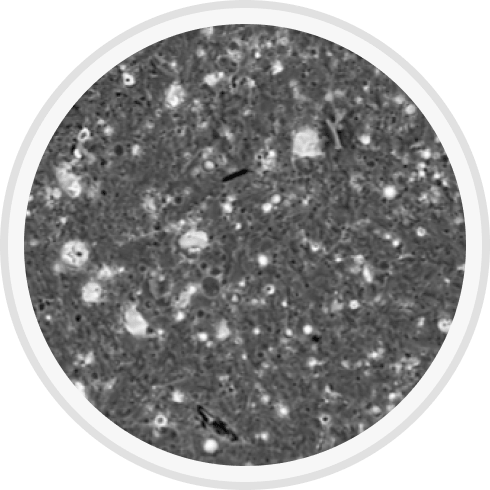

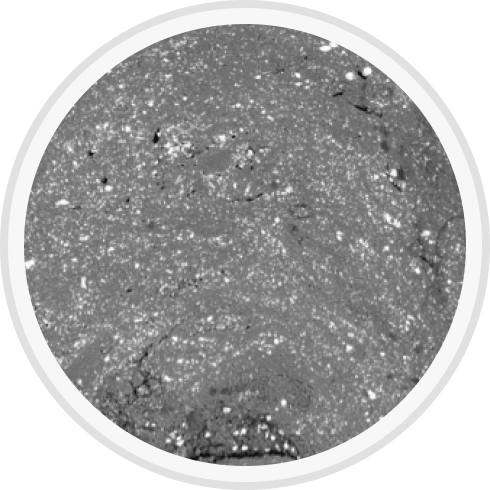

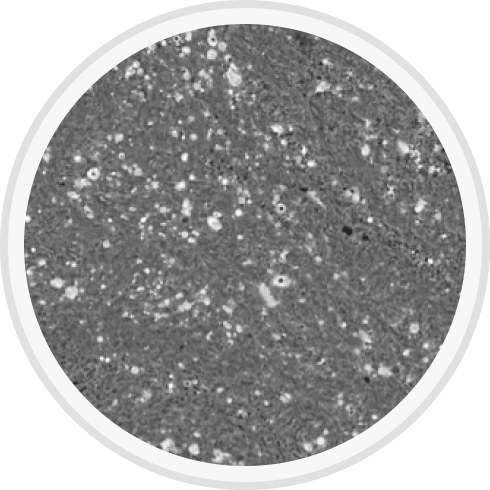

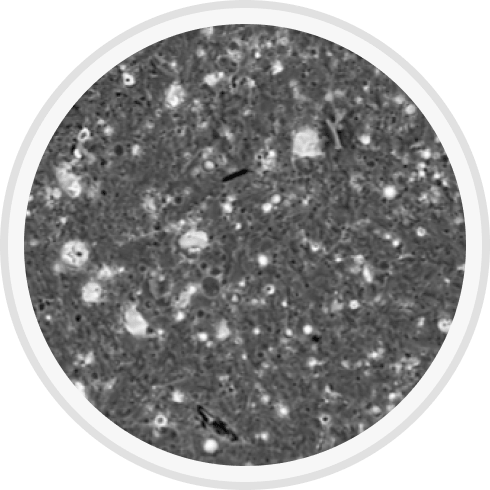

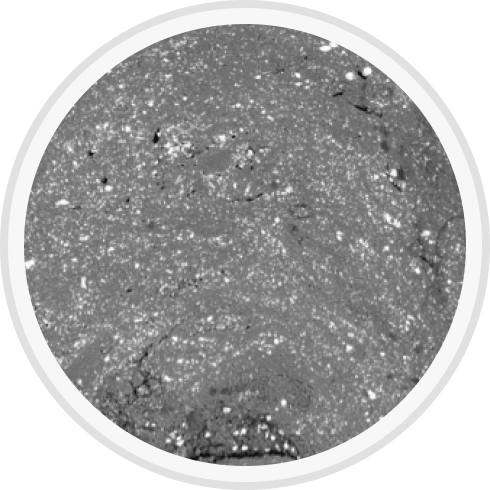

Cross-section of a Urea MST granule at 3 different magnifications using scanning electron microscopy and energy dispersive X-ray (showing uniform distribution of Micronized Sulphur particles in yellow)

80x

Traditional Elemental Sulphur Products

Range: 500 µm

350x

Competing Elemental Sulphur Products

Range: 100 µm

500x

Micronized Sulphur Technology (MST®)

Range 50 µm

The production process results in homogenous product contains MST® particles uniformly dispersed throughout each granule.

Minimal to no enrichment has been experienced in production and handling facilities, substantially reducing the safety risk associated with sulphur dust.

Simple, Safe, Single-Step micronization process

The process uses a liquid as the medium for micronization, forming a safe environment

No chemical reactions

Low temperature, low-pressure process

No exotic metallurgy required

Average particle size < 7 microns

Sulphur concentration in dry products of up to 20%

Proven technology, operating plant at Nutrien’s White Springs Florida plant

Quick and easy start-up and shutdown

Easy “bolt-on” integration into existing fertilizer production facilities

Virtually non-intrusive and no downtime production loss during construction

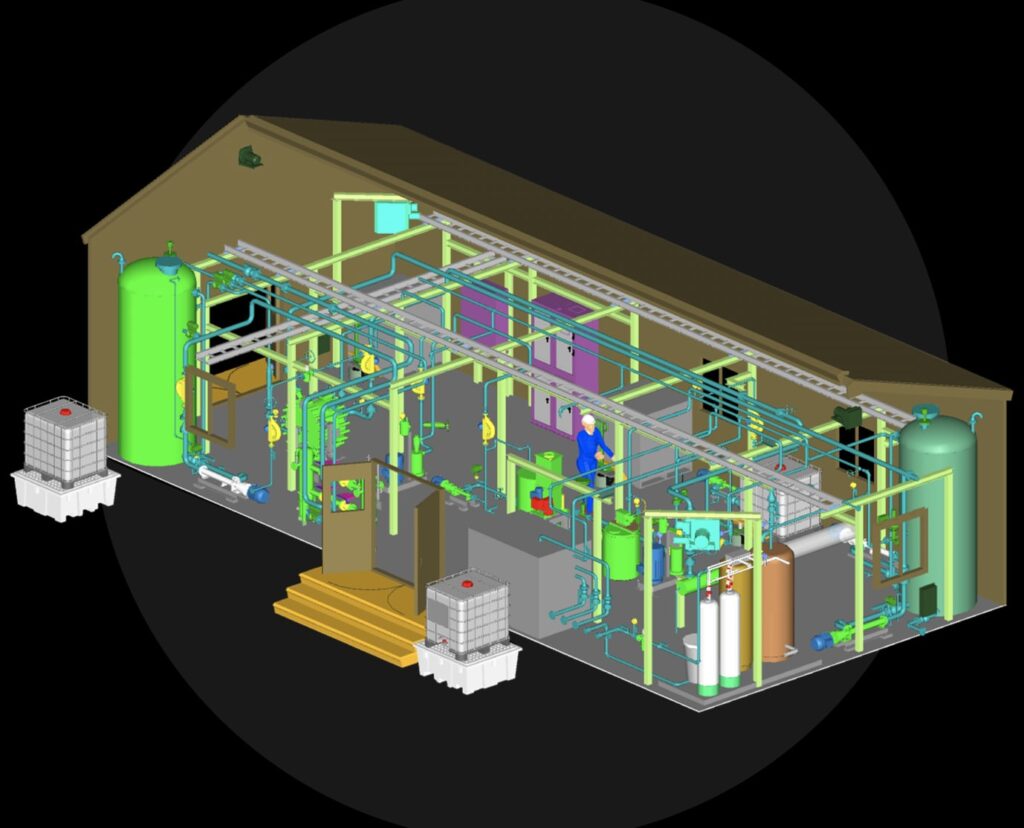

The 3D Model of a Modular MST® facility shown reflects a typical design and size of the MST® process with capacity of 50 KMT of sulphur per year.

The configuration shown is a representative size. The actual size may vary depending on local conditions and product selection. Configuration shown is 15.5m by 7m.

Patented economical process for producing high-value micronized Sulphur from low- value elemental Sulphur

Average particle size < 7 microns (average can be controlled)

Can be integrated into existing NPK fertilizer (Nitrogen, Phosphorus, and Potassium Fertilizer) products/operations

Other commercial opportunities in fungicides, feed, rubber & latex, paints & inks

Patented economical process for producing high-value micronized Sulphur from low- value elemental Sulphur

Average particle size < 7 microns (average can be controlled)

Can be integrated into existing NPK fertilizer (Nitrogen, Phosphorus, and Potassium Fertilizer) products/operations

Other commercial opportunities in fungicides, feed, rubber & latex, paints & inks

Sulvaris developed Micronized Sulfur Technology (MST®) as

Sulvaris Inc., Calgary, and Machinefabriek Kreber B.V., Netherlands, are

Latest News

A Fertilizer containing micronized elemental Sulphur and Ammonium Sulphate

A brand-new Ammonium Sulphate fertilizer containing micronized sulphur

A revolutionary carbon-based, ammonium phosphate product

A revolutionary carbon-based, ammonium sulphate product

19% N, 21% S, 5% C (19-0-0-21-5C)

SGN: 290-320 (2.9-3.2mm)

Uniformity index > 60

Crushing strength > 4.5 kg (10lb)

HIGH RTA and LOW dust

Flexible process allows for alteration of nutrient analysis and carbon content, as well as the addition of micronutrients

A Broad Acre Potash and Sulphur Fertilizer

Potash MST® granules produced at IFDC

A brand-new potash fertilizer containing micronized sulphur

Traditional Elemental Sulphur Products

(75-2000 micron size avg 960)

Specialty Products with Elemental Sulphur

(50-200 micron size avg 150)

Sulvaris MST® Particle Size

(1-12 micron size avg 7)

A broad acre phosphate fertilizer containing micronized elemental Sulphur

Phos MST® has all three nutrients evenly dispersed through every granule

Traditional Elemental Sulphur Products

(75-2000 micron size avg 960)

Specialty Products with Elemental Sulphur

(50-200 micron size avg 150)

Sulvaris MST® Particle Size

(1-12 micron size avg 7)

A broad acre fertilizer containing micronized elemental Sulphur and Urea

A brand-new Urea fertilizer containing micronized sulphur

Traditional Elemental Sulphur Products

(75-2000 micron size avg 960)

Specialty Products with Elemental Sulphur

(50-200 micron size avg 150)

Sulvaris MST® Particle Size

(1-12 micron size avg 7)

A broad acre liquid fertilizer containing micronized elemental Sulphur

Advantages

On average, Liquid MST® has provided greater yield responses than ammonium thiosulfate across all site-years studied.

The sulphur in MST® is immobile in the soil until it is oxidized to sulphate. Liquid MST® has less leaching than ATS and can be readily integrated into fall and early spring applications.

Liquid MST® does not have a high salt or nitrogen component that can damage germinating seeds, or foliage.

This is a high analysis sulphur product, meaning a lower volume of product is required to achieve sulphur requirements.

Liquid MST® is suitable for side dress applications.

Liquid MST® has a lower carbon footprint than tradition sulphur products such as ATS or AS.

Liquid MST® allows all of the crop’s sulphur requirements to be provided from one source, creating an opportunity to choose an environmentally responsible N source.